The goal of recycling is simple: waste less of what we use. A circular economy, discussed in detail later on, is based on reducing waste.

It is a fact that the natural resources that the world relies on will eventually run out. In the recycling view, that’s not a problem to leave for future generations to figure out. People, companies, organizations and governments are focusing on changing the way we do things so we use less, throw less away and regenerate more naturally.

The problem of waste is twofold: where material comes from (and the byproducts of accessing it), and where it goes after it’s been used. Recycling reduces waste by connecting the two ends of this lifecycle. Generating less waste mitigates the impacts to our environment that result from producing, using, and discarding products.

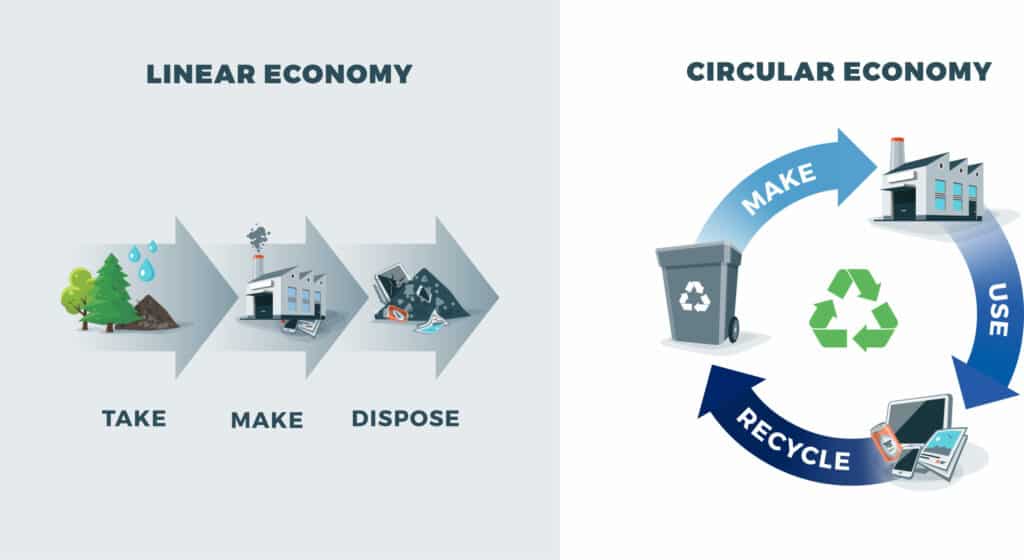

The ideal is zero waste, and shy of that, we can still believe in “less is more.” That means moving away from our current, take-make-waste economy to more of a circular, make-use-recycle economy. This kind of comprehensive closed-loop system is called a circular economy, and it’s a phrase you’re likely to hear more of from leaders in global environmental policies.

What Is A circular economy?

A circular economy “…is based on the principles of designing out waste and pollution, keeping products and materials in use, and regenerating natural systems. (It is) opposite of a linear economy where raw materials are sourced, products are made, products are used and products are discarded.”

Another definition is “…a model of production and consumption, which involves sharing, leasing, reusing, repairing, refurbishing and recycling existing materials and products as long as possible” to extend the lifecycles of products.

As a rule of thumb, the more uses you get out of something, the less wasteful it is. Think about how much use you expect to get out of a car, a laptop, a pair of jeans, and a drinking straw, just as examples. How long do you hold on to each, and how many individual uses do you get out of them? Not everything can be reused infinitely, but you get the most value out of something by using it as much as you can. That’s the idea behind waste reduction through re-use, repair, refurbishing and recycling.

The goals of a circular economy are to use less, waste less, and remain profitable. Linear economies are set up with profit as the ultimate objective and resistant to anything that hits the bottom line, while a circular economy asks us to think instead of the through line as being vital to long-term sustainability.

CLOSED-LOOP VS. OPEN-LOOP SYSTEMS

There are two types of material use and recycling systems: open loop and closed loop.

In open-loop systems, raw material is mined or harvested, processed into products, used and sometimes reused, and then it exits as waste. Rather than circulating back to the beginning over and over again, it returns to the beginning of the utilization loop once or only a handful of times before becoming waste.

Open-loop systems are linear; raw materials go in one end and broken, obsolete or used up products come out the other. These systems put off disposal for a while, and slow the need for new natural resources somewhat, but ultimately require new raw materials. They are sometimes referred to as “take-make-waste” systems.

In open-loop systems, recycled products are dismantled and the materials are processed — heated, exposed to chemical reactions, melted, chopped, crushed, shredded and so forth — to either make them usable in a secondary product or prepare them for disposal.

A common example of a material that makes its way through an open-loop recycling system is plastic. Plastic from recycled bottles is used to create fabrics like fleece, but doing so changes the form of the plastic and degrades its quality. When the fleece garment reaches the end of its life, the plastic can’t be recycled again; it becomes waste, instead. Paper, likewise, has a limited re-use cycle, owing to the fibers in its structure becoming shorter every time it is shredded back into pulp for new paper.

By comparison, in closed-loop systems raw material is mined or harvested, processed into products, used in what’s called the “utilization stream,” then reused and recycled. All of the materials are broken down, melted or otherwise reformed into the same or different products, recycled and reformed again. The materials continuously cycle through the closed loop over and over again, forever, generating the least possible material waste.

A great example of a closed-loop recycling system is the way we create, use and reuse the aluminum in cans. Once the raw aluminum enters the loop, it never has to leave; all of the aluminum can be recycled and reformed into new cans without any negative impacts on the aluminum, and using fewer resources to produce it. In fact, metals are among the materials that can be recycled practically infinitely without losing their valuable properties.

BENEFITS OF CLOSED-LOOP RECYCLING

Waste reduction is the primary benefit to closed-loop recycling but there are several others:

Landfills

We’re close to reaching the limits of our landfills in the United States. In fact, by 2021 the average landfill will only have about 15 years of life left. After that, where will all our trash go? Closed-loop recycling is the alternative to turning more land into landfills.

Natural Resource Consumption

The more we recycle, the less raw material we need to make new stuff. We don’t have to mine as much ore, extract as much coal and oil to generate electricity, or degrade as much soil in the process of growing plants (e.g., cotton for clothing).

Pollution

Generally speaking, reusing raw materials rather than mining or growing translates to less air and water pollution from manufacturing processes and waste incineration, as well as less hazardous waste to deal with.

Energy

Typically, it does not take as much energy to manufacture products from recycled materials as it does to start from scratch. This is true of metals: creating steel from iron ore is massively more “expensive,” from an energy-consumption standpoint, than creating it from existing steel.

SUSTAINABILITY

By reusing materials, manufacturers are able to get closer to their sustainability goals that are either mandated by governments or, as is becoming more common, demanded by shareholders, customers, and employees.

All of these are also goals of creating and operating a circular economy.

INCREMENTAL STEPS TO A CIRCULAR ECONOMY

In many ways a circular economy is a closed-loop system on a much larger scale. Rather than one utilization stream, it’s the combination of hundreds, thousands and even hundreds of thousands of them.

A lot of innovation and leadership is needed to create, operate and perfect all the closed-loop systems required for a circular economy. Even as we move toward that goal, open-loop recycling still plays a role in achieving some of the objectives of a circular economy, especially in the short term.

Regardless of whether the materials you’re getting rid of are part of an open-looped or closed-loop system, recycling as much as you can makes a difference.