Unlike many other materials, metals can be recycled time and time again without their properties getting degraded. That’s one reason why steel is the most recycled material in the world.

Recycling scrap metal helps to fulfill both a financial incentive and an environmental imperative. Read on to find out about the different types of scrap metal, the recycling process, and the benefits of giving metals new life.

What Is Scrap Metal Recycling?

Scrap metal recycling refers to the recovery and processing of recyclable metal materials from end-of-life products and structures so they can be reintroduced as raw material for the production of new goods.

Types of Recyclable Metals

Scrap metal is categorized into two types: ferrous and non-ferrous. Here’s the difference between the two:

FERROUS METALS

The term “ferrous” is derived from the Latin word for iron and refers to both iron and steel. Iron is the second most commonly occurring metal in our planet’s crust. Its natural magnetism is what gives the Earth a magnetic field. Because nearly all ferrous metals are magnetic, metal scrap yards often use massive electromagnets mounted on excavators to load and unload ferrous scrap from trucks and move it around the yard.

The largest sources of scrap ferrous metals in the U.S. are found in durable products such as appliances, tires, and furniture. According to the Environmental Protection Agency, 27.8% of all recycled ferrous metals in 2018 came from these durable goods, which equals a whopping 4.7 million tons.

The following items are also made of ferrous metals:

- Construction and building materials such as I beams, ductwork, rebar, and electrical wiring

- Transportation parts and products such as cars, railroad scrap, rotors, drums, and motor blocks

- Containers and packaging

Scrap metal is also a byproduct of steel manufacturing. This type of scrap — including clippings, busheling, and skeletons — is easy and valuable to recycle back into the same stream it came from, because it isn’t altered and therefore doesn’t require as much processing.

Non-FERROUS METALS

Because non-ferrous metals don’t lose their chemical properties during the recycling process, they can be endlessly recycled. There’s a long list of non-ferrous metals, but some of the most common base metals include aluminum, copper, nickel, lead, tin, and zinc. Precious metals like gold and silver also belong to the non-ferrous category. Each of these has a wide variety of uses.

Although non-ferrous scrap makes up only 10% of the total material recycled in the U.S., it provides half the total value of the scrap recycling industry’s earnings. For example, the U.S. exported $10.4 billion worth of non-ferrous scrap metal to more than 95 countries in 2018 alone.

Because recycling operations purchase non-ferrous scrap on a per-pound basis, it’s usually more valuable to recyclers. However, prices for non-ferrous tend to fluctuate more than for ferrous metals.

Non-Recyclable Metals

Unfortunately, not all scrap metal can be recycled, but the list of non-recyclable metals is exceptionally short. It includes radioactive metals like uranium and plutonium as well as toxic metals like mercury. However, there are some metals or metal items that scrap yards will not take, often for liability reasons. Other items they may charge to take because it takes extra steps to process them. It’s wise to check with a yard before you bring something in if you’re not sure.

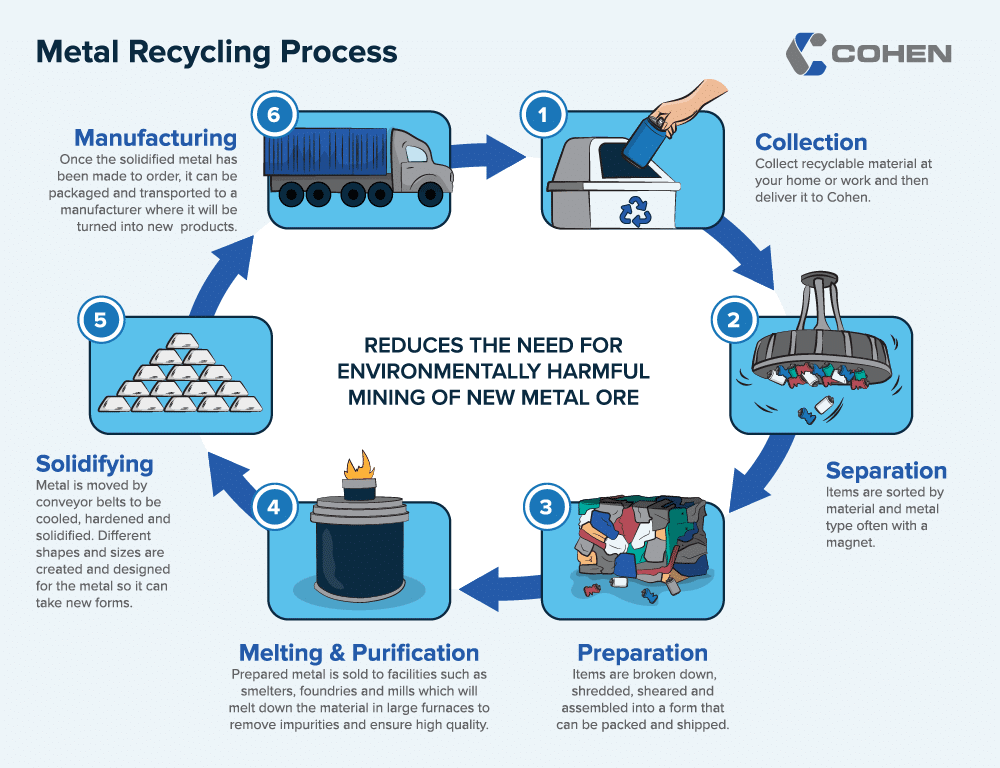

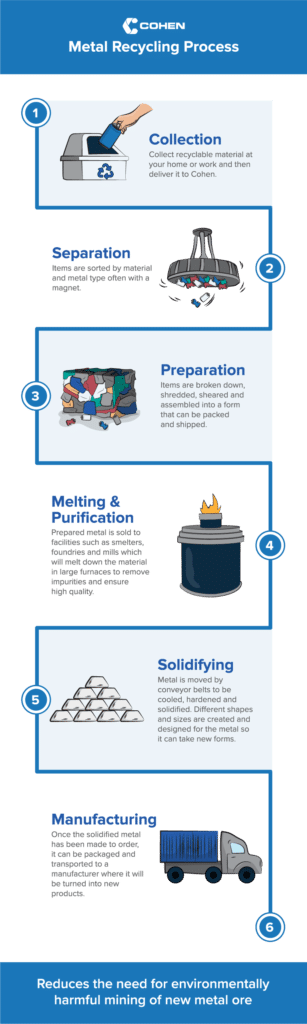

The Scrap Metal Recycling Process

The process of turning your old soda cans, cars, or cooking pans into an assortment of brand new products is quite involved and fascinating. Here are the seven different stages:

1. Know The Basics

Before you bring your materials to a metal scrap yard, there are a few actions you can take.

To learn about scrap metal pricing and whether there’s a minimum amount of material you must bring in, locate and contact a scrap metal yard near you. Then, as best you can, separate the metal from all other materials, such as plastic or paper. The general rule is that a product must contain 50% or more metal, so set aside items that hit that mark. Afterward, you may want to use a magnet to identify which items are ferrous and which are non-ferrous. This isn’t strictly necessary but can help you get unloaded and weighed faster at the yard.

Before you head out, make sure you have your ID handy. To help crack down on the theft of scrap metal, most recyclers require some form of identification.

2. COLLECTING

When you take scrap metals to a scrap metal yard near you, the materials first go through a weigh-in station. At some locations, you can even stay in your car while a scale operator unloads and weighs your material. Then, you’ll get a weight ticket to cash in.

In addition to scrap metal collectors, metal is collected through curbside recycling services or from large generators or scrap dealers. Curbside and public recycling services typically only take common household metal items like cans, and not the full range of recyclable metals. That’s where scrap recyclers come in.

3. SORTING

Scrap yards use a number of different means to sort and separate metal, including visual identification, spectrometers, magnets, and electrical currents. It’s important to keep metals grouped together because they need to meet certain quality standards, which means no cross-contamination with other metals and materials. Scrappers can get more money for their metal if they do some of this work ahead of time and dismantle things that are made of mixed materials – for example, a metal bike with rubber tires and handles.

4. PREPARING INTO FORMS

To make the melting process more efficient, metals have to be cut down to specific sizes and shapes. . Scrap metal is made to order; the scrap yard already knows what shapes, compositions, and weights of metals their customer needs. Shredding, torching, and baling are all examples of ways that scrap metal can be prepared, depending on its final use.

Once the metal is sized and processed, it leaves the scrap yard and goes on to the next customer in the chain: the mills, foundries, and smelters that use scrap to make new metal.

5. MELTING AND REFINING

The process to melt down scrap metal will vary from one metal to the next, and the level of purity that’s needed. Melting metals makes the impurities rise to the top where they can be separated from the remaining metal. Some metals go through additional refinement through processes like electrolysis to yield something as close as possible to primary, or new, metal.

The alternative source for making metal is metal ore that is mined out of the ground, referred to as virgin metal. The two can be used together – scrap metal, once purified, retains all the same properties as its parent metals. Using scrap helps save energy and costs compared to virgin metal.

6. SOLIDIFYING

Once cleared of contaminants, molten metal is transformed as it solidifies. There are a number of different forms it might take, and plants are specialized in what types they create. Examples include bars, wire, coil, and sheets. Sometimes, chemicals are added to the metal to make it denser or change its properties.

After the solidifying stage is finished, the metal is ready to be used again.

7. MANUFACTURING

Usually, the foundry or mill is not the end user of the new metal. It goes on to other sectors of the manufacturing stream, like automakers, robotics, aerospace, public works projects, and a vast array of consumer goods. Through repair and reuse, the lifecycles of those products can be maximized until it’s finally time to recycle them again.

BENEFITS OF METAL RECYCLING

The reasons to recycle scrap metal are plenty. Individual sellers, manufacturers, and the planet we call home all reap the many rewards. Here are several of the greatest benefits of scrap metal recycling:

1. IT PUTS CASH IN YOUR POCKET

First and foremost, there’s a financial incentive for recycling scrap metal, as you get paid for the materials you bring to a scrap yard.

The pricing fluctuates based on market conditions and other factors, and additional fees may apply. To learn about the general industry trends, you can use third-party apps and websites that aggregate the average prices by geography, but keep in mind these will be averages and not guaranteed. Your best bet is to reach out to a scrap metal yard near you to learn what the day’s prices are.

2. IT KEEPS HAZARDOUS WASTE OUT OF LANDFILLS

In a landfill, many metals can take a long time to break down into elements small enough to return to the earth – hundreds, if not thousands, of years, doing nothing but taking up space. Some metals like lead and mercury are hazardous and will leach into the surrounding soil and water over time, and should be disposed of safely instead. For all these reasons and more, keeping such items out of landfills by bringing them to a scrap yard reduces waste in important ways.

3. IT SAVES ENERGY

Recycling scrap metal requires far less energy than the manufacturing of new products with virgin raw materials. According to the Connecticut Department of Energy and Environmental Protection, recycling a single aluminum can saves enough energy to power a 100-watt light bulb for almost four hours.

With such high energy savings, consumers get cheaper products while greenhouse emissions drop, so it’s truly a win-win.

4. IT SAVES BUSINESSES MONEY

Recycling scrap metal not only puts money in your wallet, but it also saves manufacturers money by allowing them to significantly reduce their production cost.

5. IT CREATES JOBS

According to a report published by the Institute of Scrap Recycling Industries, the U.S. scrap recycling industry is a powerful economic engine that provides 531,510 jobs and generates nearly $13 billion in tax revenues per year nationwide.

START RECYCLING YOUR SCRAP METAL TODAY

Only 34% of metals were recycled in 2018. Given the fact that nearly every kind of metal is recyclable, that number is far too low. To do your part in helping the planet — and earn money while you’re at it — find a scrap yard near you.

Why Choose Cohen For Metal Recycling?

Cohen is a family-owned ferrous and non-ferrous metal recycling company founded in Middletown, Ohio with a reach that spans the globe. Covered drive-thrus and friendly, knowledgeable staff help make every scrapping experience simple and rewarding. Dedicated to the same values we were founded on, Cohen is People Powered Recycling. Bring in your metal recyclables today!