Of all the resources our world consumes, few are more vital than metal, and few are easier to recycle. Unlike many other materials, metal can be repeatedly scrapped and recycled, reducing the need for carbon-intensive mining. There’s probably a metal recycling facility near you, even if you don’t know where it is.

As efficient as the metal recycling process is, scrap metal purchasers still face a major obstacle in their collection: proper identification of the metals they receive. A wide variety of non-ferrous metals can be repurposed, and ferrous metals like iron and steel are also highly recyclable, but they must first be categorized correctly. Metal mills and foundries rely on their suppliers, including scrap companies, to provide exactly the metals they need, so classification is important.

Getting the most value out of scrap metal relies on knowing how to properly identify and sort scrap metals, especially scrap steel.

Ferrous vs. Non-ferrous Metals

There are two basic categories of metal: ferrous and non-ferrous. Ferrous metals contain iron, and many different types of steel used today are ferrous metals. They all get classified differently, but we’ll talk about that more later. Some examples of ferrous metals include:

- Pig iron

- Cast iron

- Stainless steel

- Wrought iron

- Mild steel

As their name implies, non-ferrous metals consist of all metals that aren’t iron or alloys of iron. Examples include:

- Copper

- Zinc

- Aluminum

- Bronze

- Brass

- Tin

- Nickel

- Precious metals (Silver, Palladium, Rhodium, etc.)

Each of these non-ferrous metals have their own commodity price, and they differ from the prices of ferrous metals. Stainless steels also have a separate value, so once ferrous and non-ferrous metals are sorted to be sold at market price, ferrous metals must be subdivided even further.

Ferrous Metal Categories

“Ferrous” is pretty much synonymous with “steel,” and steel is an alloy, meaning that it contains varying concentrations of other elements to give it the desired material properties. Because of that, only certain types of steels can be used to manufacture certain parts. As an example, tool steels must possess a high degree of hardness, temperature resistance, and ability to maintain a sharp cutting edge, so they are often alloyed with elements like tungsten and molybdenum. Softer steels with a greater malleability would not be appropriate if the purpose was to manufacture a steel used for tools.

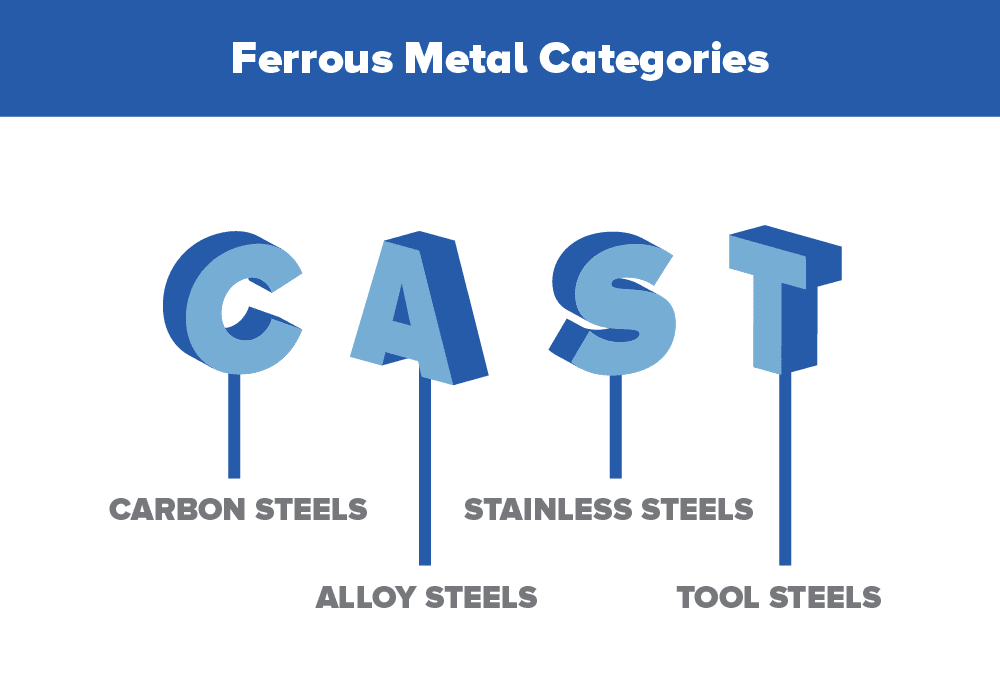

There are four primary categories that ferrous metals fall into. They vary according to alloy composition and carbon content, and can be easily remembered by the acronym CAST. They are:

- Carbon steels (up to 2.5% carbon content)

- Alloy steels (0.1–1% carbon content)

- Stainless steels (less than 1.2% carbon content)

- Tool steels (0.7–1.5% carbon content)

There is some overlap in carbon content between these categories. These trace elements will give your ferrous metal significantly different properties, and metal recyclers must class them accordingly in order to sell them. Otherwise, buyers may not have the right steel to produce their goods, and will not return for another purchase.

Ferrous Metal Uses

Because different steel types have different material properties, some steels are more likely to be found in one industry than another. Some industries require incredibly specific material properties, so it’s essential that they purchase the right kind of scrap metal, or the quality of their products will suffer.

Some of the most common stainless steel types and the corresponding industries that use them are:

- 17-4: Often used in the food and aerospace industries

- 300: Non-magnetic

- 304: Kitchenware

- 310: High-temperature equipment

- 316: Food and boating industries

- 321: Aircrafts and exhaust systems; i.e., manifolds

- 400: Magnetic, high-temperature, and have no nickel

There are many types of stainless steel for manufacturers to choose from, and a great many material properties must be carefully considered to select the right one. All of that consideration is futile without a supply of the proper steel class they need, which is why correct identification is critical.

Identifying Ferrous Metal Types

Scrap metal processors like Cohen sort out their steel before it’s sent off to clients. Scrappers who really know their steel can sometimes increase the value of their scrap by sorting it properly, but how do they know which is which? Some steels are stamped with an SAE or AISI serial number to identify their material type, but recyclers don’t always have it so easy.

Inspection

Experienced scrap metal recyclers may be able to identify some metals by checking for a few traits. The most notable of these are:

- Luster. Some materials can hold their shine more than others. The chromium content of some ferrous metals makes them corrosion-resistant, and can make them visibly brighter than others.

- Weight. Even if two metals look identical, one may be much heavier than the other. You’ll have a hard time distinguishing between aluminum and some stainless steels by their color, but pick them up and you’ll see that stainless steel is noticeably heavier.

- Magnetism. Perhaps the primary way to distinguish austenitic stainless steels from other ferritic steels is that the latter are magnetic, while the former are not. Take a magnet with you to see what sticks! Magnetic steels are generally worth more in scrap than those that don’t stick.

Although helpful with rough approximations, these physical tests still won’t tell the whole story of your steel. You’ll need something more for that.

X-ray Fluorescent Analysis

To precisely identify which type of steel they have on their hands, the professionals use a technique called x-ray fluorescent analysis, or XRF. This is done by a machine that bombards the metal with x-ray radiation. The incoming x-rays excite the energy levels of the electrons within the metal, and, as a result, they release a subsequent fluorescent x-ray that can be detected by the machine.

Each element releases an x-ray with a unique frequency, giving them a kind of fingerprint by which they can be identified. This fingerprint enables scrap metal recyclers to know the exact composition of the metal they have on hand, so they can sort it out according to the four major steel classes listed above.

It’s unlikely that the average homeowner or curbside scrapper has an XRF device, of course – and that’s just fine. You don’t need to know what kind of metal you have or exactly what it is composed of in order to recycle it with us.

Cohen: Your Leading Scrap Metal Recycler

Scrap metal recycling is one of the most efficient repurposing processes around, but it has to be done correctly. There are many types of scrap metal both within and without the ferrous metal category, and all of these have different properties which make them suited for different industries. Sorting steels according to their classes takes the right expertise and toolset and, at Cohen Recycling, we have both.

We’re one of the nation’s largest ferrous and non-ferrous scrap metal recyclers, and we can sort your scrap according to spec. If you’re looking for a scrap metal recycler near you, we’re who you’re looking for. Whether you’re a manufacturer seeking a steel scrap supply or a scrapper looking for a place to deposit your ferrous metals, contact us today, and we’ll provide you with a scrap metal solution.