Construction scrap material can quickly pile up on job sites, impacting your efficiency and even creating a safety hazard. It’s important that when you’re going into a new job, you have a plan in place to collect and remove the waste you generate.

Most of that material is recyclable and valuable, especially the metal: steel, iron, copper, and aluminum. Separating these materials and selling them for scrap helps you recoup costs and reduce waste.

Here are some thing to consider when planning for construction scrap or demolition waste:

Construction Scrap MATERIAL

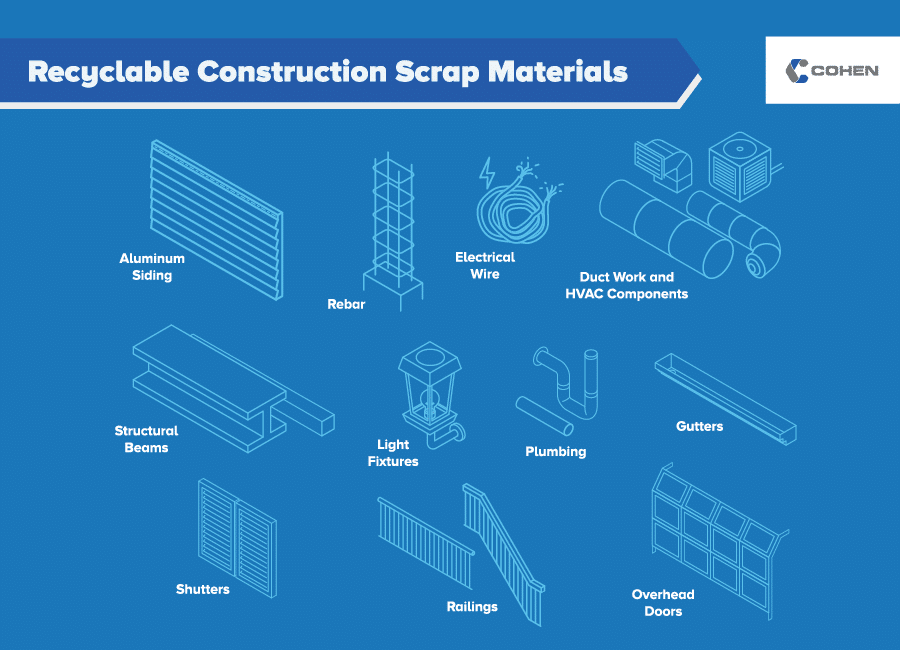

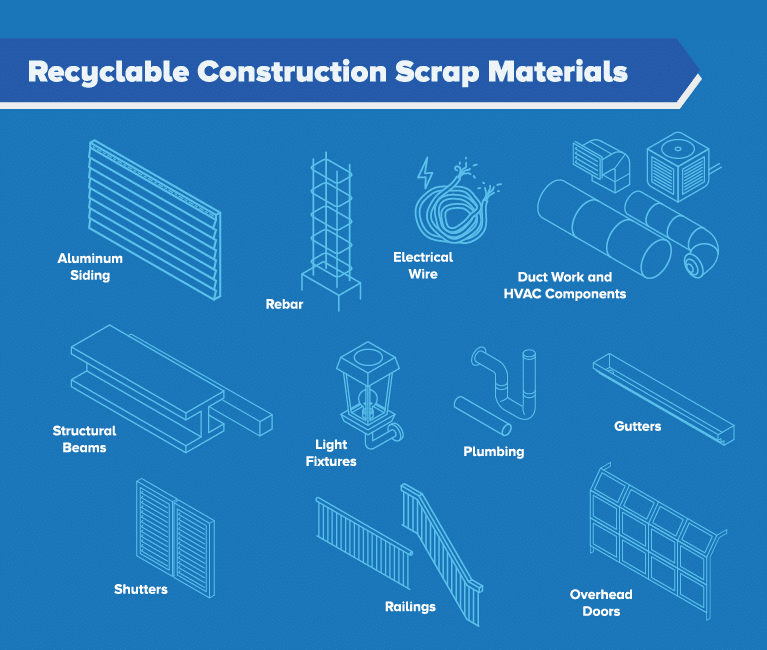

What kind of scrap will be generated on your site? It depends on the job, but here are some common sources of scrap:

- Aluminum siding

- Rebar

- Electrical wire

- Duct work and HVAC components

- Structural beams

- Light fixtures

- Plumbing

- Gutters

- Shutters

- Railings

- Overhead doors

Before a demo job, it’s a good idea to walk the site and identify what parts should be manually dismantled and separated before tear-down begins. Construction scrap is usually generated along the way as pieces are trimmed to fit the application.

Volume

The most convenient way to handle scrap is to have a container on-site to gather as you go. The type of scrap you have and the volume you expect to generate will help you and your scrap recycler determine what kind of container or containers you’ll need, and how often you might need them hauled and replaced over the course of the job.

Preparation

The most valuable scrap is the scrap that has already been prepared to go directly to a mill. The fewer stops your scrap material has to make before it’s ready to sell to mills, the more costs you can eliminate. You can skip this step if you’re in a hurry, but you’ll lose some value if you do.

The large pieces of metal that typically come of off demolition jobs are usually not ready for the mill and need to be cut down to smaller pieces. An excavator mounted shear can cut through metal like it’s wet spaghetti, while a mobile shredder produces a finer material. Cohen can send our mobile equipment to your demolition site to prepare your scrap on the spot and ship it directly to the mill – one less thing to worry about.

Transportation

You need a scrap company who can reliably transport your containers offsite in a timely manner, and provide empty containers as necessary, to keep your job on schedule and on budget. Ask questions of your vendor’s logistics manager to make sure they’ll be able to meet your needs.

Cohen knows how much a delay in the flow of scrap can ruin your day. We maintain our own fleet of trucks, drivers, and mechanics so we can ensure reliable service every step of the way.

RECYCLING = TAKING RESPONSIBILITY

According to the EPA, “Reducing and recycling [construction and demolition] materials conserves landfill space, reduces the environmental impact of producing new materials, creates jobs, and can reduce overall building project expenses through avoided purchase/disposal costs.”

Keeping recyclable materials in circulation reduces the need to mine and drill new metal ores, which does irreversible damage to the environment. Creating new material from raw resources takes far more energy than recovering recyclable material from the waste stream. So not only does recycling protect natural resources, it keeps material costs down overall and adds value to the economy.

GET A SCRAP QUOTE TODAY

Consult with Cohen to manage your scrap and keep your operations running smoothly. Cohen collaborates with your team to create innovative, customized solutions suited to the job.